5.7.7 Spreaders

Spreaders may be used to drain rainwater from a higher roof surface with a catchment area not exceeding 15 m2 provided the following conditions are satisfied:

- When discharging onto a tiled roof, the lower section is sarked a minimum width of 1800mm either side of the point of discharge extending down to the eaves gutter.

- When discharging onto a corrugated roof, a minimum width of 1800 mm on either side of the point of discharge is sealed for the full length of the side laps.

- The increased roof water volume from the upper roof is not to enter any seam of the roof covering of the lower roof.

No spreader is to have its discharge entering any part of any building.

- Spreaders are to discharge all roof water onto roof coverings in the direction of flow, avoiding discharging onto laps on lower roof sheets and tiles.

- When discharging an upper roof catchment onto a lower roof, the total roof area including the additional upper roof catchment area is to be considered for inclusion when sizing the lower roofing, gutters and downpipes.

- Spreaders do not discharge on sheets or tiles discharging to valleys.

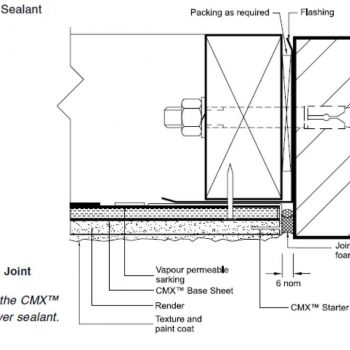

8.7 All Other Flashings and Cappings

b) Parapet cappings: Parapet cappings to be fixed to parapet walls at intervals not exceeding 500 mm with masonry anchors and cleats that permit longitudinal expansion and contraction. A minimum fall of 3 degrees to be provided across the width of the flashing, to divert water back onto the roof coverings so as to prevent the water from dripping down the fascia causing unsightly staining.

8.2 Fastening

Roof flashings and cappings are to be fastened as given in Table 8.2(A) and the following:

(e) Joints in flashings and cappings to be 25 mm and fastened at intervals not exceeding 40 mm. Joints are to lap in the direction of fall.

5.8.3 Fastening and sealing with sealants

Joints in aluminium/ zinc, aluminium/zinc/magnesium alloy-coated steel, prepainted steel flashings and cappings are to be fastened at intervals not exceeding 40 mm and silicone sealed with neutral cure silicone sealants.

Sealants are to be sandwiched between the laps of the joint to provide a positive seal and to protect the silicone sealant from exposure to ultraviolet radiation.

8.6.1 Collar Flashings

Where any part of the roof surface is penetrated by any pipe, pole, duct, flue, shaft, cable or tank support, the penetration is to be flashed to prevent the entry of rainwater, and to permit the roof surface and penetrating object to expand and contract without detrimental effect to any part of the roof. In addition, particular attention is to be paid to the following:

Pondage Colar flashing to permit the total drainage of the area above the penetration